What is Alloy Steel? A Definitive Guide

Alloy steel is a type of steel that contains carbon and other alloying elements to enhance its properties. These alloying elements include chromium, manganese, titanium, tungsten, nickel, and more. The added elements help bolster properties such as hardness,...

What is Sheet Metal Bending? A Complete Guide

Sheet metal bending refers to the fundamental process in metalworking that involves taking flat metal sheets and shaping them into three-dimensional items by applying force. Sheet metal bending is common throughout various industries, including manufacturing,...

Remembering Marlene Kelly

Marlene Davis Kelly (1935-2022) We would like to express our deepest sympathies to the family of Floyd Kelly, co-founder of Precision Machine Fabrication for the loss of his wife of 60 years, Marlene Davis Kelly. Marlene passed away this past Tuesday, September 6th at...

ISO 9001:2015 Certified

Precision Machine Fabrication is a world-class contract manufacturing company specializing in close-tolerance sheet metal fabrication. We are proud that we are registered under the ISO 9001:2015 standard. Our policies and procedures are independently audited annually...

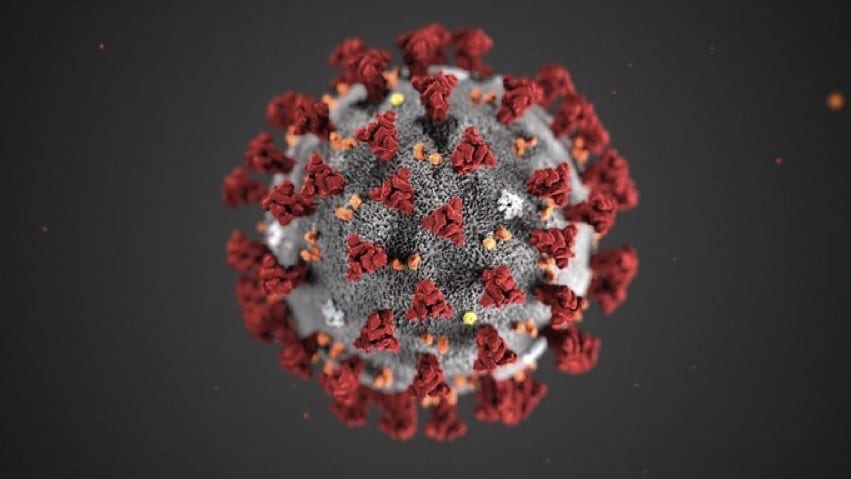

PMF and COVID-19

As our world struggles to contain the COVID-19 (Coronavirus) pandemic, our thoughts are with all those affected by this disease. Our thanks go out to researchers on the front lines fighting to defeat this virus and the health care professionals caring for the sick....

Celebrating 40 Years

In December of 1978 two City of Raleigh firefighters started a small company out of a rented storage space to fabricate close-tolerance custom metal parts for a wide range of industries. This December, now 40 years later, we gathered together to celebrate this...

Going Green!

Here at PMF we care about American metal manufacturing as well as the future of our planet. So, we strive to lessen our impact where we can. That’s why we’re excited to announce that this week PMF has taken a significant step toward reducing our carbon...

Closed 3/25 (Good Friday)

PMF will be closed on Friday, March 25th in observance of the Good Friday holiday. We wish everyone a safe and happy Easter weekend and will return to work on Monday, March 28th.

2015 Christmas Lunch

We held our annual Christmas Lunch for employees on Wednesday, December 23rd. We had a delicious catered lunch of ham and turkey, sweet potatoes, baked beans, and apple cobbler. We also held our employee gift drawing and passed out this year's limited edition company...

Video Interview-Kenny Holley

Check out what Kenny Holley, the head of our engineering department, has to say about our switch to E2 Shop Systems by Shoptech Software a little over one year ago. Learn how it helps us focus on our process so that we can consistently deliver the best sheet metal...

919-231-8648

Start a Project in Raleigh Today!

Ready to get started working with one of the top machine fabrication companies in Raleigh, NC and beyond?

Contact us today for additional information and one of our representatives will be in touch in just a few business days!