Sheet metal laser cutting services deliver clean edges, tight tolerances, and consistent precision. At PMF, our CNC-controlled lasers cut a wide range of metals with speed and accuracy—reducing lead times, material waste, and the need for secondary processing.

Sheet Metal Laser Cutting Process

At PMF, sheet metal laser cutting is the critical first step in our manufacturing process. Using advanced CNC laser systems, we cut flat parts from sheet metal with exceptional accuracy and minimal material waste. This stage sets the tone for the entire fabrication workflow, which is why we emphasize tight tolerances and clean edge quality from the very beginning.

Our laser cutting equipment is specially designed to handle a wide range of materials and thicknesses. Each cut is programmed using customer-supplied design files, ensuring the part geometry is executed exactly as intended. By starting with such precision, we lay the groundwork for faster downstream fabrication, better fit during assembly, and a higher-quality finished product overall.

Tools and Technology Used for Sheet Metal Laser Cutting Services

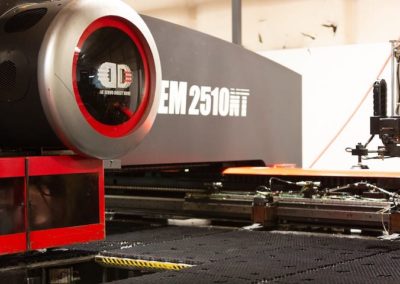

PMF’s laser cutting services are powered by a fleet of advanced CNC machines designed for precision, speed, and reliability. At the center of our operations are five high-performance Amada systems—including Vipros, Apelio, and EM2510 models—paired with our 4,000-watt Mitsubishi CO₂ laser. These machines are ideal for cutting flat sheet metal up to 1/8″ thick and producing intricate shapes with remarkable consistency.

For heavier-duty applications, we offer:

- 4 Amada Pulsar laser capable of cutting up to 1/4″ thick steel

- A 4,000-watt Mitsubishi laser that handles material up to 1″ thick

All metal laser cutting is done in our CNC department, where advanced laser heads and turret punch presses allow for high-precision cuts, complex perforations, and custom geometries. Most systems are equipped with automated material loading and unloading, enabling lights-out manufacturing for fast, cost-efficient turnaround. Additionally, intelligent nesting software optimizes material layout, reducing waste and maximizing efficiency on every job.

Metal Laser Cutting Capabilities

PMF offers high-precision sheet metal laser cutting services tailored to a wide range of materials and project scales. Whether you need a single prototype or high-volume production, our CNC-controlled lasers deliver clean cuts, tight tolerances, and excellent repeatability.

We work with the following materials and thicknesses:

- Mild steel: Up to 1″ thick

- Stainless steel: Up to ½″ thick

- Aluminum: Up to ⅜″ thick

- Other metals: Custom requests welcome—contact us for details

Our advanced equipment and skilled technicians allow us to cut complex geometries with minimal waste and high part-to-part consistency. From intricate enclosures to industrial-grade components, our laser cutting capabilities support a variety of industries with speed, accuracy, and efficiency.

Why Choose PMF for Sheet Metal Laser Cutting Services

At PMF, we bring together cutting-edge CNC automation and over 40 years of manufacturing expertise to deliver laser cutting services that are precise, reliable, and tailored to your specific needs. Whether you’re producing a single prototype or scaling up for full production, our process is built for accuracy, efficiency, and long-term value.

What sets us apart:

- High-Precision Cuts: We achieve tight tolerances with minimal heat-affected zones, ensuring consistent part quality.

- Durability: Laser-cut parts maintain their structural integrity, even under load or in demanding applications.

- Lights-Out Manufacturing: Our automated systems operate around the clock, reducing lead times and increasing output.

- Scalability: We handle everything from custom one-offs to large production runs with repeatable quality.

- Smart Nesting Software: Advanced material optimization minimizes waste and helps keep your project cost-effective.

Our laser cutting services support industries such as aerospace, electronics, medical devices, industrial machinery, construction, and consumer products. When you partner with PMF, you gain a trusted team that’s committed to delivering speed, precision, and results you can count on.

Testimonials/What Our Customers Say About Us

Fantastic work! Our robotics team was hurting for a quick turnaround in aluminum sheet metal and was not let down. We ended up winning the Quality Award at our first event for a fully sheet metal robot. We will definitely be working with PMF in the future.

My experience with PMF was nothing but professional. In my position as a procurement manager, I sometimes have to react at a moment’s notice when the need arises. My initial contact with the team at PMF was extremely helpful, and the subsequent follow-up was near immediate. I look forward to building a relationship where they are a partner that I can count on being there.

We have used PMF for over 10 years. It doesn't matter if it is a prototype or a million-dollar order, the experience has been the same. OUTSTANDING! From engineering to production to shipping, they are the best. We couldn't land the orders we do without their expertise to back us up. Thanks, PMF.

919-231-8648

Request a Quote for Sheet Metal Laser Cutting Services

Ready to get started? Request a fast, accurate quote tailored to your cutting specifications and production timeline.

Frequently Asked Questions About Sheet Metal Laser Cutting Services

What is sheet metal laser cutting?

Sheet metal laser cutting uses a focused laser beam to cut precise shapes from flat metal sheets, producing clean edges and tight tolerances with minimal material waste.

What materials can PMF laser cut?

We work with a wide range of materials, including:

- Aluminum

- Carbon steel

- Stainless steel

- Coated metals (galvanized, galvalume, aluminized, pre-painted)

- Copper, brass, and select plastics

What are the maximum thicknesses you can cut?

Our laser cutting systems can handle:

- Carbon steel: Up to 3/4″

- Stainless steel: Up to 1/2″

- Aluminum: Up to 3/8″

What’s the largest part you can laser cut?

We can accommodate sheet sizes up to 60″ x 120″, making us well-equipped for both small components and large-format parts.

What’s the largest part you can laser cut?

We can accommodate sheet sizes up to 60″ x 120″, making us well-equipped for both small components and large-format parts.

Is laser cutting better than CNC punching?

Laser cutting offers greater precision and versatility—especially for complex shapes—but CNC punching may be more cost-effective for simpler parts and high-speed perforation work.

What’s the best metal for laser cutting?

Stainless steel is often the ideal choice for sheet metal laser cutting. It cuts cleanly, produces smooth edges, and typically requires no secondary finishing.

What are the benefits of laser cutting over other methods?

Laser cutting offers several key advantages, including:

- Greater precision with clean, burr-free edges

- Tighter tolerances for high-performance applications

- Minimal material waste through efficient nesting

- Faster turnaround due to automated, high-speed cutting

- Reduced need for secondary processing, saving time and cost

This makes it an ideal solution for both prototyping and full-scale production.

Companies We’ve Worked With

Choose PMF for Sheet Metal Laser Cutting Services

With decades of expertise, advanced laser systems, and ISO 9001:2015 certified quality, PMF is the trusted partner for manufacturers who demand precision and performance. Whether you’re cutting prototypes or scaling up production, we’re ready to deliver.

Explore Our Capabilities