What is Fabrication?

So what is metal fabrication? Fabrication is a versatile manufacturing process that involves the construction of objects and parts from raw materials, often starting with sheet metal or other malleable materials. This process is essential in various industries, including construction, automotive, aerospace, and electronics, among others. The sheet metal fabrication process typically begins with the selection of the appropriate raw material, followed by several techniques to shape and assemble the components into the desired final product.

At Precision Machine Fabrication, the fabrication process primarily involves the following techniques:

- Bending: Bending is a process in which sheet metal or other materials are subjected to force, causing them to deform and take on a specific angle or shape without fracture. This technique is commonly used to create angles, channels, and other bent components.

- Punching: Punching involves the use of a punch and die set to cut holes or specific shapes in the material. This process is vital for creating perforations, slots, or other openings required in the final product.

- Cutting: Cutting is the process of separating the material into specific shapes and sizes. Various methods like shearing, sawing, or laser cutting can be employed to achieve precise cuts in the raw material.

- Welding: Welding is a crucial joining technique in fabrication where two or more pieces of material are fused together using heat and pressure. This ensures a strong bond between the components, creating a unified structure.

Apart from these core fabrication techniques, Precision Machine Fabrication also undertakes assembly and powder coating processes:

- Assembly: Assembly involves putting together various fabricated components, fasteners, and other parts to create a complete product. This step ensures that all the individual pieces work cohesively and function as intended.

- Powder Coating: Powder coating is a finishing process where a dry powder is applied to the fabricated surface. The coated product is then heated, allowing the powder to melt and form a durable, protective layer. This enhances the product’s appearance, provides corrosion resistance, and improves overall durability.

It’s important to note that while fabrication encompasses a wide array of techniques, it primarily focuses on forming and joining materials to create a final product. On the other hand, machining, as mentioned earlier, is a different manufacturing process that involves the removal of excess material from the workpiece to achieve the desired shape and dimensions. Both fabrication and machining are crucial in modern manufacturing, catering to different production requirements and applications.

What is Machining?

Machining and fabrication are different because machining entails a broader variety of strategies that utilize alternative technologies. Machining is a manufacturing process that involves the use of various cutting tools and machinery to remove excess material from a workpiece, thereby shaping it into a desired final form. Machining aims to create finished products with precise dimensions, smooth surfaces, and specific shapes, often used in automotive, aerospace, electronics, and other industries.

Some common machining practices include:

- Milling: Milling involves rotating cutting tools that have multiple cutting edges. These tools remove material from the workpiece’s surface to create flat, contoured, or multi-dimensional shapes.

- Drilling: Drilling is the process of creating holes in the workpiece using rotating cutting tools called drills. This technique is essential for various applications, such as creating holes for fasteners or allowing the passage of fluids and gases.

- Turning (Lathe work): Turning is a machining operation performed on a lathe. The workpiece rotates while a cutting tool is brought into contact with it, resulting in the removal of material and the creation of cylindrical or conical shapes.

- Grinding: Grinding is a precision machining process that utilizes abrasive wheels to remove small amounts of material from the workpiece’s surface. It is employed to achieve very tight tolerances and smooth surface finishes.

- Boring: Boring is a machining operation that enlarges or refines existing holes in the workpiece, often with the aid of a single-point cutting tool.

- Shaping and Planing: Shaping and planing are techniques used to remove material from the workpiece’s surface in a linear motion, resulting in flat surfaces with consistent thickness.

- Electrical Discharge Machining (EDM): EDM is a non-traditional machining process that uses electrical discharges between an electrode and the workpiece to erode material, enabling the creation of intricate and complex shapes.

Machining processes are carried out with precision CNC (Computer Numerical Control) machines, which are programmed to follow specific instructions and produce consistent and accurate results. CNC machining has revolutionized the industry by increasing efficiency, reducing errors, and enabling the production of complex parts that would be challenging or impossible to manufacture using manual techniques.

What is Manufacturing?

When comparing manufacturing vs fabrication, the difference is clear. Manufacturing is a comprehensive process that involves the large-scale production of goods from design to distribution. It encompasses various stages, including design, fabrication, assembly, and quality control. The fabricated parts are then assembled to create the final product. These parts are assembled using mechanical fastening or welding to produce the finished products. Precision Machine Fabrication’s comprehensive approach allows them to meet diverse customer needs in the manufacturing industry.

Manufacturing can be categorized into mass production, batch production, and custom production, depending on the scale and nature of production. Mass production involves the continuous production of identical products, while batch production produces specific quantities in batches. Custom production caters to individual customer requirements, creating unique products. PMF’s expertise in both fabrication and manufacturing enables them to deliver high-quality and tailored solutions to their clients.

Learn more about our manufacturing services.

Custom Sheet Metal Fabrication

At Precision Machine Fabrication, we specialize in custom sheet metal fabrication for a variety of industries. We fabricate sheet metal parts, assemblies, and chassis for the commercial, electronics, computer, communications, medical, home appliance, retail, industrial, and power-management industries.

At first glance, however, people can assume that we are a machine shop. We are more accurately considered a metal fabrication shop. Many people don’t know the difference between the two facilities and often get the two confused.

What is A Fabrication Shop?

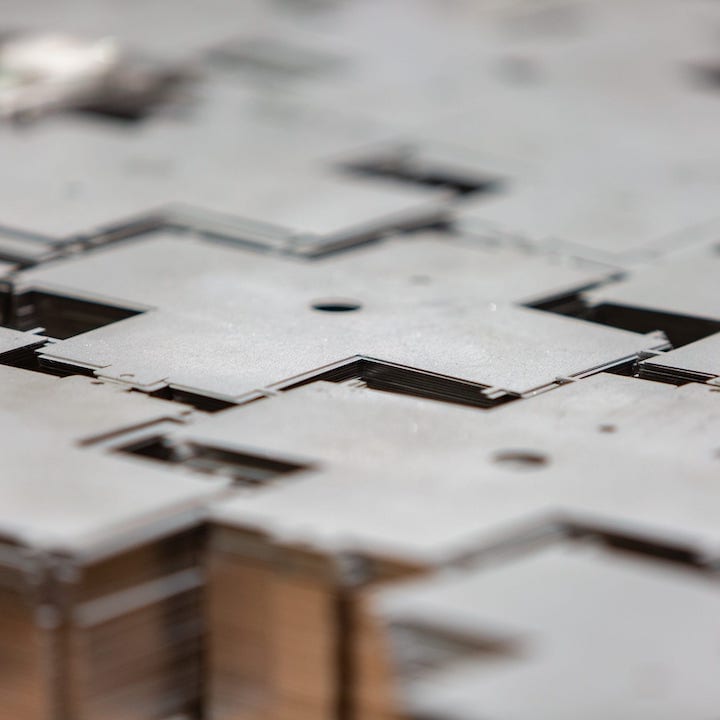

A metal fabrication shop is a facility that generally starts with flat sheets of metal and goes on to laser cut, punch out, bend, weld, powder coat, and assemble finished parts.

What Does A Machine Shop Do?

Most machine shops, on the other hand, start with blocks of metal (round, square, or rectangular solid rods or tubing) and create finished parts through sawing, milling, drilling, and turning processes.

Sheet Metal Fabrication Shop

If you think about it in regards to the art world, machine shops “sculpt” metal into a finished form by removing the excess material while fabrication can be more closely related to making origami through cutting, bending, and forming a flat sheet into a finished form.

While we are not a machining company, PMF does offer an in-house machine shop. But, it is primarily focused on small-run jobs that supplement our primary production portfolio. We also utilize this equipment to modify tooling and develop fixtures in-house.

Metal Fabrication Projects We Don’t Do

While Precision Machine Fabrication does perform metal fabrication projects in a wide variety of industries, there are certain areas we cannot focus our efforts in. For example, PMF does not offer HVAC or ductwork services. Despite the equipment and processes being similar in this type of fabrication, the business models are very different and there is little overlap. As a result, we focus on high-precision, close-tolerance fabrication of custom parts for OEM’s instead.

Precision Machine Fabrication does not offer residential fabrication services. Our internal process as a fabrication shop is better suited for medium to high-volume production. Furthermore, we do not have the resources to provide cost estimates and design services necessary for most residential projects. We are generally unable to perform “one-off” jobs or backyard projects.

In order to be competitive in the medium- to high-volume market, our production schedule must remain firm. We find that it’s both disruptive and not profitable for us to focus on these individual one-time jobs for individuals. If you’re looking for help with this type of project, however, give us a call and we will try to suggest local fabrication shops better suited to help you.

Finally, please keep in mind that our team is happy to work on designs supplied by our customers but we do not develop original designs ourselves.

What Our Customers Say

919-231-8648

Start a Project in Raleigh Today

Ready to get started working with one of the top machine fabrication companies in Raleigh, NC and beyond? Contact us today for additional information and one of our representatives will be in touch in just a few business days!

Explore Our Capabilities